Techflow Enterprises Pvt Ltd is one of the biggest and most trusted suppliers of products like Air pollution control device, Air pollution control equipment, Bag filter, Pulse jet dust collector, Pulse jet bag filter, De-dusting system, Bag house, Cassette type filter, Reverse air cleaned bag filter, Silo Vent filter, Fabric Filter, Dust Recovery system, online cleaning bag filter, Off line cleaning bag filter, Centrifugal fans and blowers, Flue gas emission control system, furnace fume extraction system , welding fume extraction system and pneumatic conveying system, Electro static precipitator, ESP in India with exports all around the world.

Techflow Enterprises Pvt Ltd has been serving many industries like Foundry, Particle board plants, Steel mills, steel plants, TMT making industry, dryer, Aluminium plant, aluminium smelting, Waste to energy plant, WTE, mineral industry, DRI plant, rubber recycling, cement mill, cement plant, crushing plant, boiler flue gas, ceramic plant, kiln, pharmaceutical plant, Food Plant, Dairy Plant, cattle feed plant and many more industries.

Discover more| Fume Extraction System And Filtration System For Furnace |

|---|

FES for AOD (Argon oxygen decarburization Furnace)

|

FES for EAF (Electric Arc Furnace)

|

FES for LRF (Ladle Refining Furnaces)

|

FES for Induction Furnaces

|

FES for Zinc Furnaces

|

FES for TRF (Tilting rotary furnace) & Skelner furnaces

|

FES for Exothermic Reaction Furnace

|

CNC Plasma and Laser Cutting

|

Welding Fume Extraction TECHFLOW provides optimum solution for issues related to fumes which are generated during different kinds of welding operations like TIG, MIG, SMAW, Brazing and Soldering. We at Techflow provide feasible and finest solutions for the fume extraction during welding operations as mentioned below:-

|

Centrifugal fans and blowers for steel plant Techflow is a Supplier of various industrial grade centrifugal fans and blowers used for following applications:-

|

Dust collection systems / Air pollution control system / bag filters for various application of steel plant, DRI plant, Crusher houses, captive power plant TECHFLOW is a manufacturer and supplier of dust extraction systems, de-dusting system, pulse jet bag filters for crushing plants like DRI plant, Stone Crushing, Mineral Grinding to control the dust particles at following points:-

|

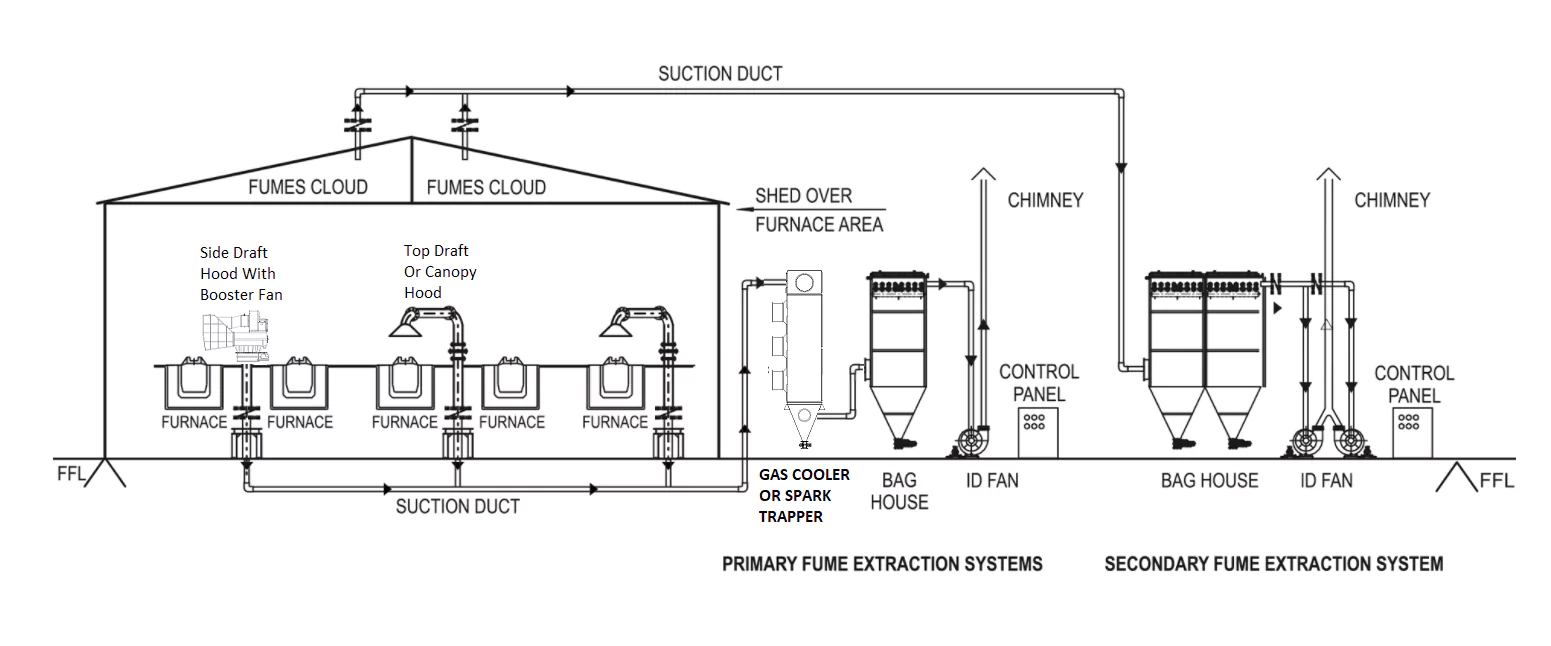

Induction furnace & arc furnaces are offered to control their resulting pollution control by exctraction thro’ swilling/ water cooled hoods or third hole. The extracted hot fumes & gases (often flame laden) are taken away to TECHFLOW air pollution treatment & furnace air pollution control systems. The TECHFLOW furnace pollution control system consists of Primary cyclone / secondary air-water cooler & finally thro’ a pulse-jet or reverse air bag house. A powerful ID fan & duct-stack system is provided as ordered.

The workers / employees find it uncomfortable to work in the polluted environment and as a result affects their output and efficiency.

Equipment - Fume Extraction with top draft suction hood, with air pollution control system, with bag filter for induction furnace

Application - Primary Furnace Fume Extraction System for induction furnace (FES for Induction furnace)

Industry - Steel, foundry, sponge, SMS, melt shops, TMT, rolling mill, steel plant

Equipment - Fume Extraction with side draft suction hood, multi cyclones, with air pollution control system, with bag filter for EAF furnace (Electric Arc Furnace)

Application - Primary Furnace Fume Extraction System for induction furnace and secondary fume extraction system for EAF furnace (primary FES for EAF furnace, Secondary FES for EAF furnace)

Industry - Steel, foundry, sponge, SMS, melt shops, TMT, rolling mill, steel plant

Equipment - Fume Extraction with side draft suction hood, with air pollution control system, with bag filter for induction furnace

Application - Primary Furnace Fume Extraction System for induction furnace (FES for Induction furnace)

Industry - Steel, foundry, sponge, SMS, melt shops, TMT, rolling mill, steel plant

Equipment - Fume Extraction with side draft suction hood, with air pollution control system, with bag filter for induction furnace

Application - Primary Furnace Fume Extraction System for induction furnace (FES for Induction furnace)

Industry - Steel, foundry, sponge, SMS, melt shops, TMT, rolling mill, steel plant

Equipment - Fume Extraction with side draft suction hood, with air pollution control system, with bag filter for induction furnace

Application - Primary Furnace Fume Extraction System for induction furnace (FES for Induction furnace)

Industry - Steel, foundry, sponge, SMS, melt shops, TMT, rolling mill, steel plant

Equipment - Fume Extraction with special side draft suction hood with booster fan, with air pollution control system, with bag filter for induction furnace

Application - Primary Furnace Fume Extraction System for induction furnace (FES for Induction furnace)

Industry - Steel, foundry, sponge, SMS, melt shops, TMT, rolling mill, steel plant

Equipment - Fume Extraction with side draft suction hood, with air pollution control system, with bag filter for induction furnace

Application - Primary Furnace Fume Extraction System for induction furnace and secondary fume extraction system for induction furnace (primary FES for Induction furnace, Secondary FES for Induction furnace)

Industry - Steel, foundry, sponge, SMS, melt shops, TMT, rolling mill, steel plant

Equipment - Fume Extraction with side draft suction hood, with air pollution control system, with bag filter for induction furnace

Application - Primary Furnace Fume Extraction System for induction furnace and secondary fume extraction system for AOD furnace (primary FES for AOD furnace, Secondary FES for AOD furnace)

Industry - Steel, foundry, sponge, SMS, melt shops, TMT, rolling mill, steel plant

Equipment - Fume Extraction with travelling suction hood, with air pollution control system, with bag filter for exothermic reaction furnace

Application - Primary Furnace Fume Extraction System for induction furnace (FES for exothermic reaction furnace)

Industry - Steel, foundry, sponge, SMS, melt shops, TMT, rolling mill, steel plant

Equipment - Fume Extraction with side draft suction hood, multi cyclones, with air pollution control system, with bag filter for LRF furnace (Ladle Refining Furnaces)

Application - Primary Furnace Fume Extraction System for induction furnace and secondary fume extraction system for LRF furnace (primary FES for LRF furnace, Secondary FES for LRF furnace)

Industry - Steel, foundry, sponge, SMS, melt shops, TMT, rolling mill, steel plant

Equipment - Fume Extraction with top draft suction hood, with air pollution control system, with bag filter for Zinc melting furnace. This is also known as zinc recovery systems or dust collection system for zinc furnace or bag filter for zinc recovery

Application - Primary Furnace Fume Extraction System for zinc furnace (primary FES zinc making induction furnace)

Industry - Steel, foundry, sponge, SMS, melt shops, TMT, rolling mill, steel plant, zinc melting, zinc recovery

Equipment - Air pollution control system which is also known with different names like Bag filter, dust collection system. Which is used as furnace FES

Application - supplied for dust control at various application at steel rebar manufacturing plant

Industry - Steel, foundry, sponge, SMS, melt shops, TMT, rolling mill, steel plant, rebar steel manufacturing plant

Equipment - Fume Extraction with travelling suction hood, with air pollution control system, with bag filter and ventury type wet scrubber for tilting rotary furnace (popularly known as TRF) and skelner furnace for aluminium industry or aluminium smelting

Application - Primary Furnace Fume Extraction System for tilting rotary furnace (popularly known as TRF) and skelner furnace for aluminium industry or aluminium smelting

Industry - Steel, foundry, sponge, SMS, melt shops, TMT, rolling mill, steel plant, aluminium industry or aluminium smelting

Equipment - Fume Extraction with side draft suction hood, with air pollution control system, with bag filter for induction furnace. This equipment is also known as cassette type filter widely used in foundry

Application - Primary Furnace Fume Extraction System for induction furnace (FES for Induction furnace)

Industry - Steel, foundry, sponge, SMS, melt shops, TMT, rolling mill, steel plant

Equipment - Air pollution control system which is also known with different names like Bag filter, dust collection system. Which is used as furnace FES

Application - supplied for dust control at various application at steel plant

Industry - Steel, foundry, sponge, SMS, melt shops, TMT, rolling mill, steel plant, rebar steel manufacturing plant

Equipment - Fume Extraction with side draft suction hood, with air pollution control system, with bag filter for induction furnace

Application - Primary Furnace Fume Extraction System for induction furnace and secondary fume extraction system for induction furnace (primary FES for Induction furnace, Secondary FES for Induction furnace)

Industry - Steel, foundry, sponge, SMS, melt shops, TMT, rolling mill, steel plant

Equipment - Air pollution control system which is also known with different names like Bag filter, dust collection system. Which is used as furnace FES

Application - supplied for dust control at various application at steel plant

Industry - Steel, foundry, sponge, SMS, melt shops, TMT, rolling mill, steel plant, rebar steel manufacturing plant

Equipment - Air pollution control system which is also known with different names like wet scrubber, ventury scrubber, packed bed scrubber, wet dust collection system. Which is used as furnace FES

Application - supplied for dust control at various application at steel plant and in other industries

Industry - Steel, foundry, sponge, SMS, melt shops, TMT, rolling mill, steel plant, rebar steel manufacturing plant

Equipment - Fume Extraction with side draft suction hood, with air pollution control system, with bag filter for induction furnace

Application - Primary Furnace Fume Extraction System for induction furnace (FES for Induction furnace)

Industry - Steel, foundry, sponge, SMS, melt shops, TMT, rolling mill, steel plant

Equipment - Fume Extraction with travelling suction hood, with air pollution control system, with bag filter and ventury type wet scrubber for tilting rotary furnace (popularly known as TRF) and skelner furnace for aluminium industry or aluminium smelting

Application - Primary Furnace Fume Extraction System for tilting rotary furnace (popularly known as TRF) and skelner furnace for aluminium industry or aluminium smelting

Industry - Steel, foundry, sponge, SMS, melt shops, TMT, rolling mill, steel plant, aluminium industry or aluminium smelting

Equipment -Air pollution control system which is also known with different names like Bag filter, dust collection system. Which is used for various application in crushing or DRI plants

Application - supplied for dust control at various application at crushing and DRI plant

Industry - Steel, foundry, sponge, SMS, melt shops, TMT, rolling mill, steel plant, rebar steel manufacturing plant

Equipment - ABC Fans, Cooling Fans, nose cooling fans, throat cooling fans, shell cooling fans

Application - ABC Fans, Cooling Fans, nose cooling fans, throat cooling fans, shell cooling fans are used in various applications in kiln, steel plant or DRI plant to supply fresh air or for cooling purpose

Industry - Steel, foundry, sponge, SMS, melt shops, TMT, rolling mill, steel plant, DRI plant, metallic plants

Equipment - Fume Extraction with top draft suction hood, with air pollution control system, with bag filter for Zinc melting furnace. This is also known as zinc recovery systems or dust collection system for zinc furnace or bag filter for zinc recovery

Application - Primary Furnace Fume Extraction System for zinc furnace (primary FES zinc making induction furnace)

Industry - Steel, foundry, sponge, SMS, melt shops, TMT, rolling mill, steel plant, zinc melting, zinc recovery

Equipment - Fume Extraction with travelling suction hood, with air pollution control system, with bag filter and ventury type wet scrubber for tilting rotary furnace (popularly known as TRF) and skelner furnace for aluminium industry or aluminium smelting

Application - Primary Furnace Fume Extraction System for tilting rotary furnace (popularly known as TRF) and skelner furnace for aluminium industry or aluminium smelting

Industry - Steel, foundry, sponge, SMS, melt shops, TMT, rolling mill, steel plant, aluminium industry or aluminium smelting